Making and Molding

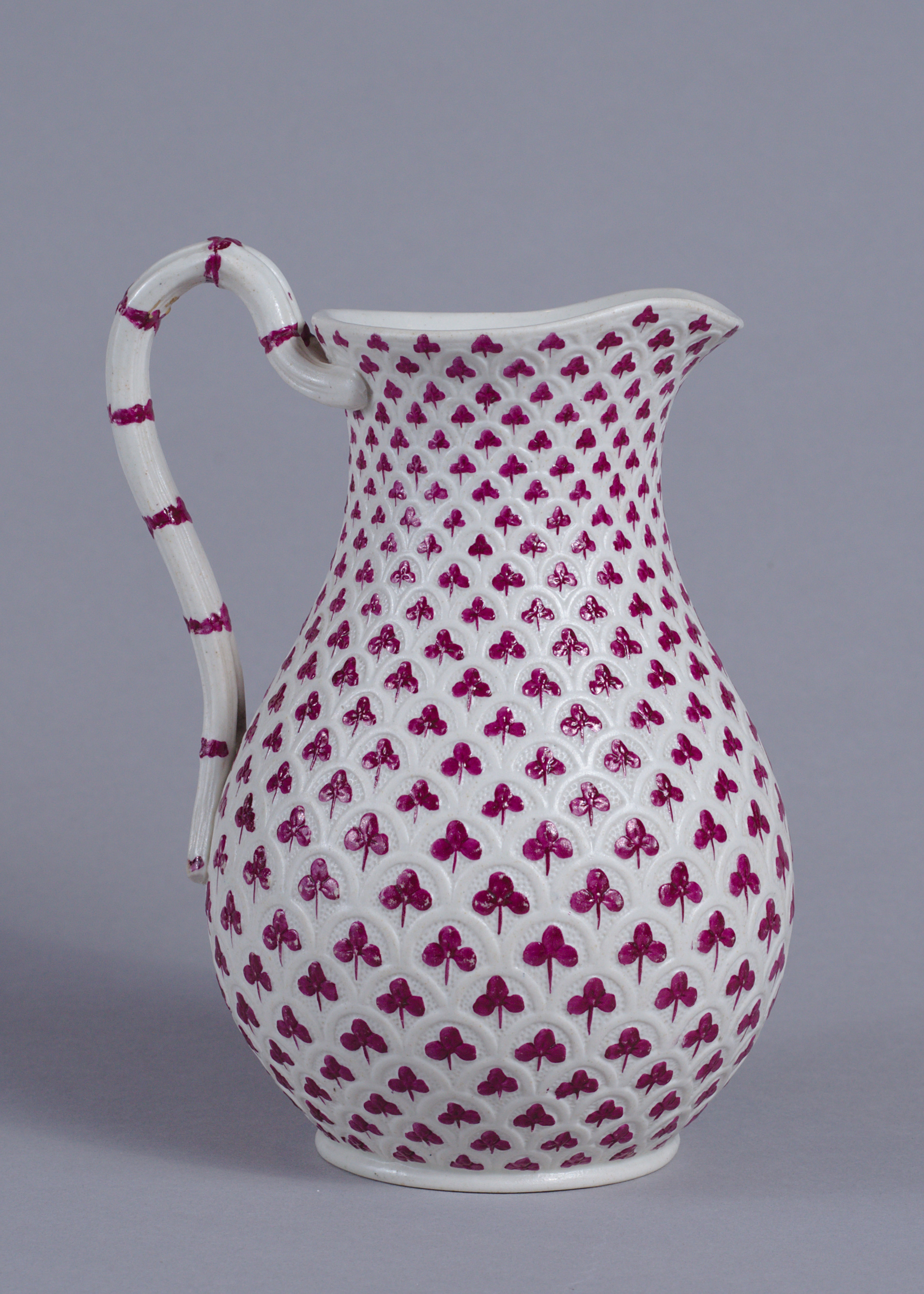

Shamrock

William Brownfield & Sons, along with many potters, produced jugs in multiple combinations and allowed people to pick their favorite color.

Color

Innovations in ceramic chemistry and processes improved colors and enameling. The early 19th century jugs were dull colors like buff, drab, or pastel greens and blues. A decade or so later decorators enameled background color by hand or dipped in colored glazes. Often the same molded jug would be colored in a variety of ways. This was largely attributed to James Mason and Mary Skerratt Mason, his wife and well-known color chemist worked to create Mason Stains in 1842, which are still be used today and is still owned and operated by the Mason family linage. Quite amazing! Inorganic oxides and carbonates were encapsulated in zirconium crystals and then ground and milled into a fine powder to be mixed into clays, slips, enamels, and glazes. This process helps keep the inorganic chemicals from leeching out of the glaze both during the firing and after during use, making them safer. The inorganic material would be mixtures of cobalt, manganese, chrome-tin pinks, iron, nickel and supporting materials such as calcium oxide and boron.